High quality and reliability combined

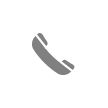

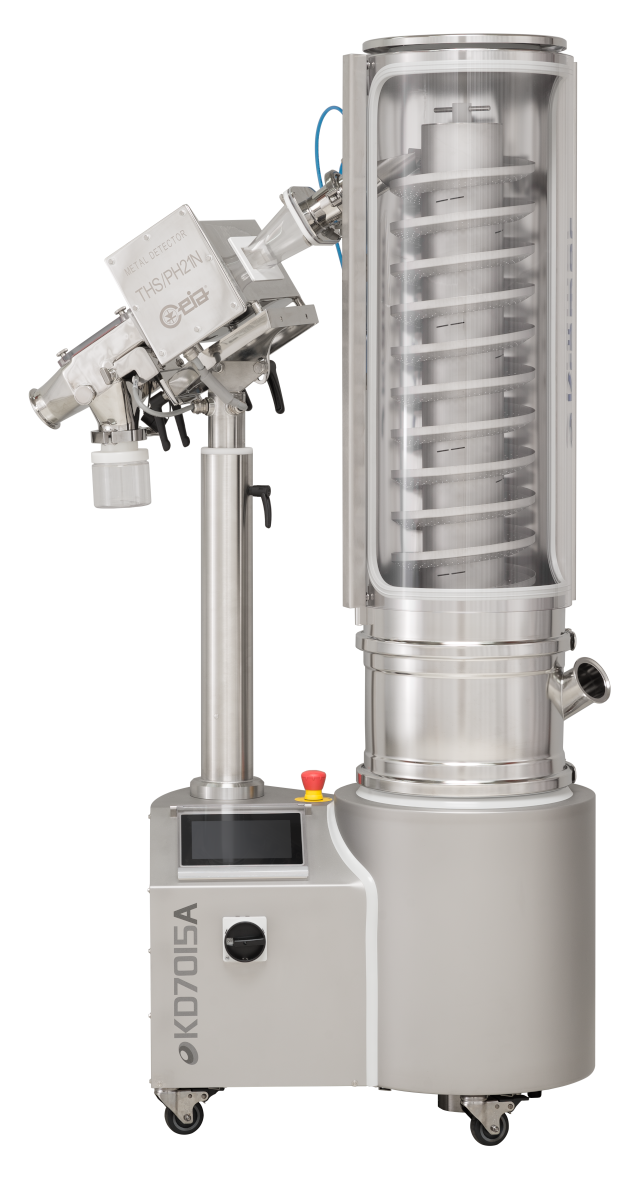

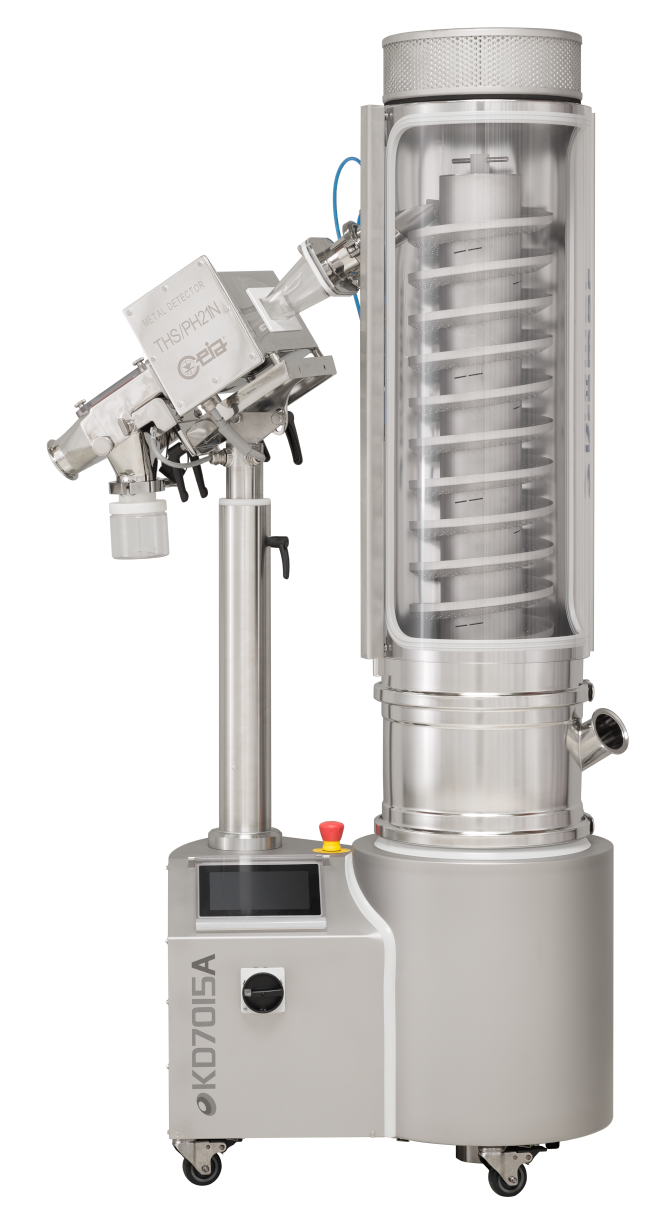

KD7015A

High performance tablet deduster with the latest technology combined with a metal detector by Ceia or Lock. Tablets are dedusted and conveyed with our unique acceleration control and helix in the most sensitive way.

- Upward conveying range of 250 to 1500 mm

- Control of deduster, metal detector and diverter with one touch-screen

- Dust-tight window

- Quiet operation < 68 dB acoustic measurements

- Featuring an acceleration sensor that assures constant vibration, independent of the load / amount of tablets in the deduster

- Optimum viewing of tablet movement with pivoting and fully removable window

- Easy height adjustment, full 360° freedom of rotation at tablet inlet

- Vibration-free housing, patented drive unit

- Compact design, minimum footprint

- Easy assembly and disassembly, no tools are needed

- Easy to clean

- Classification: Atex Zone II 2D/- Db 140 °C

- Certification: OEB4 (1 μg/m³ to < 10 μg/m³) acc. SMEPAC

- Optional, HEPA filter M-class

Conveying heights

250-1500 mm

Available Metal Detectors

Ceia and Lock

Tablet inlet Options

The optional tablet inlet adapter connection to the tablet press and upstream equipment with the use of a rectangular tablet inlet 110×70 mm. If the adapter is not being used, a hose can directly be attached to the Tri-Clamp inlet. The inlet can be rotated 360° independent of the outlet. With the use of optional inlet adapters, the deduster is easily adjustable to various tablet press discharge configurations.

WINDOW FOR EASY VIEWING

The KD7015A and KD7035A dedusters feature a PETG dust tight, hinged, lift off window for easy viewing. The window is gasketed for dust tightness to meet OEB3 and OEB 4 hazardous dust requirements. The window allows easy access to interior of the machine for cleaning disassembly without removing the housing.

Touch screen operator panel

The KD70A Series combined units utilize the KC7070A touch screen controller that allows full control of the deduster, metal detector and diverter if used from the single touchscreen. The KC7070A controller operates with an acceleration sensor in the drive to determine the optimum operating frequency for ease of operation . It also displays the deduster, and metal detector standard operating settings and parameters in one location for ease of operation. It ensures also full compliance with 21 CFR Part 11, including user login, recipe- and user-management, audit trails for alarms and full logs during operation. A strong and durable transparent cover protects the touchscreen against falling objects or scratches.

Utility Connection Ports

All Krämer dedusters feature a 2 inch Tri-Clamp vacuum dust collection port for ease of assembly of a dust collection hose. The height adjustment of the KD7015A and KD7035A dedusters are enclosed in the drive base housing along with all wiring for a clean arrangement. The base contains a lockable gas strut which allows easy vertical adjustment of the deduster to meet the press outlet height. All wiring is enclosed in the base for an uncluttered look and ease of cleaning. In addition, the power supply cable uses a quick connect plug. The quick connect plug allows for use of preassembled cables for power supply as well as signal wire options.

KC7070A – A Smart Control System

The KD7015A and KD7035A dedusters feature the new KC7070A controller with optional OPC UA machine to machine interface. This new communication protocol, between tablet press and deduster, makes it possible to exchange machine alarms, states and various dedusters functions over TCP/IP. The integrated VNC server allows remote access diagnostics from anywhere for trouble free support to minimize unscheduled downtime. This smart connect product is Industry 4.0 ready.

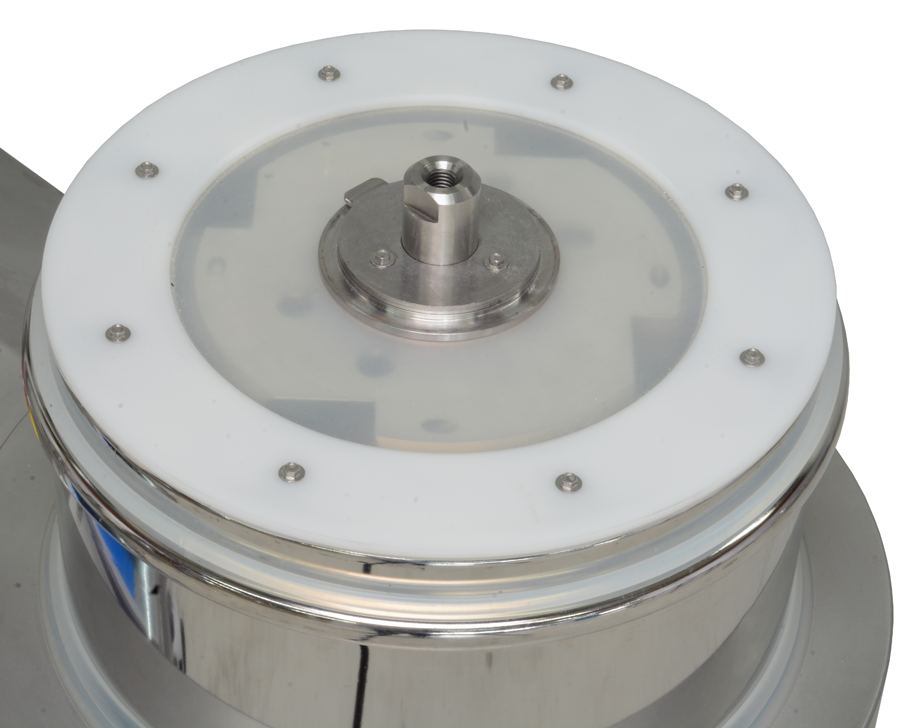

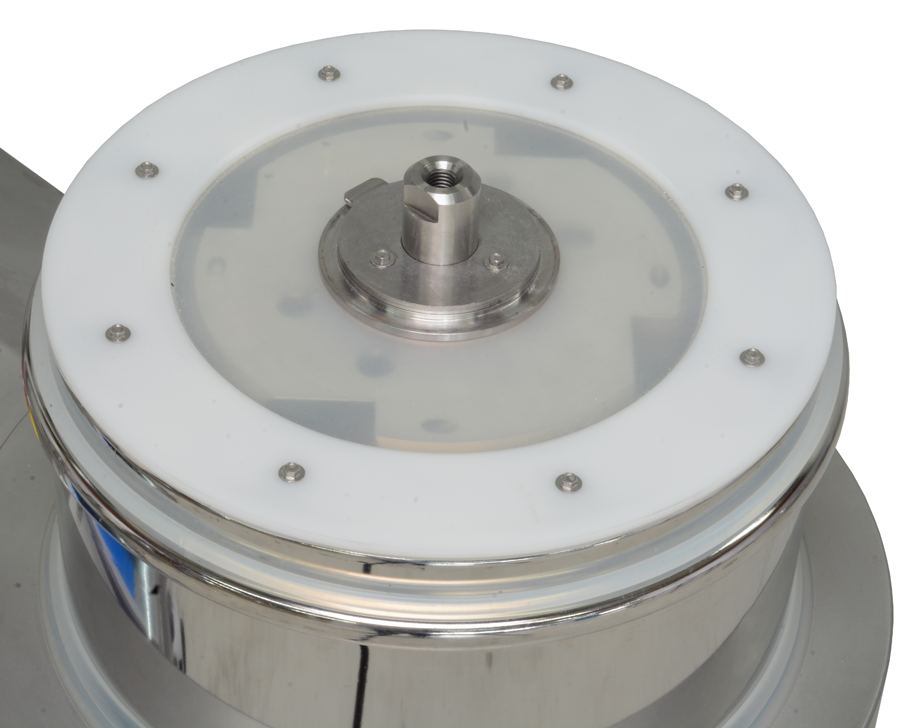

Dust tight seal membrane

The KD7015A and KD7035A deduster drives are protected from dust by a silicone membrane held down with a bolt down flange seal. The seal membrane protects all of the drive mechanical and electrical components from dust intrusion allowing for long trouble free operation and ease of maintenance.

Containment and ATEX Performance

The KD7010 and KD7030 dedusters have been independently tested and certified to meet OEB 3 and OEB 4 containment levels in accordance with ISPE – SMEPAC requirements as well as the EC Machinery Directive 2006/42/EC and Directive 94/9/EC (ATEX-95).

Dust collection Air flow sensor

The dust collection air flow sensor, an option on both models KD7015A and KD7035A, allows for monitoring the dust collection suction for confirmation that suction is correct. If suction is lost or not in the proper range an alarm will be triggered.

Specifications

Power Supply

110-240 V, 50/60 Hz

Peak current

3 A

Noise emission (1 m)

< 68 dB(A)

Elevation height

250-500-750-1000-1250-1500 mm

Outlet height

640-2150 mm

Inlet height adjustable

Inlet height

710-895 mm

Total height

1225-2730 mm

Conveying technology

Upward conveying spiral

Drive unit technology

Pat. counter weight

Footprint

705-635 mm

Product contacting parts

AISI 316L, silicone, PET-G, PUR

Weight

138-184 kg

Compressed air

Ø6/4mm, 50-100 l/min (p=1.5-2 bar)

Air extraction

2" tri-clamp, 100-250m3/h (p=10-20 mbar)

Product inlet

2.5" tri-clamp

Product outlet

2.5" tri-clamp

Protection rating drive unit

IP54

Protection rating housing/controller

IP50

Controller

7" touchscreen

Metaldetector models

Ceia THS/PH21 N DT , Lock Insight DT

Metaldetector sensitivities

Ceia SS316L=0.40 / FE=0.25 / N-FE=0.30 , Lock SS316L=0.50 / FE=0.30 / N-FE=0.35

Processing of tablets (var. forms ) Ø3-35 mm

Processing of mini/micro-tablets Ø1.5-3 mm

Processing of effervescent tablets Ø25-35 mm

Processing of capsules Nr. 4-00

Conveying speed mini/micro-tablets <Ø2.5 mm

7'500'000 tabs/h

Conveying speed tablet Ø5 mm

3'500'000 tabs/h

Conveying speed tablet Ø13 mm

410'000 tabs/h

Conveying speed tablet Ø20 mm

130'000 tabs/h

Conveying speed tablet Ø25 mm

68'000 tabs/h

Conveying speed tablet Oblong 16.3 x 7.6 x 5.7 mm

425'000 tabs/h

Explosion protection ATEX 94/9/EG

II 2D/- Db 140 °C

OEL Level acc. SMEPAC

OEB 3-4

cGMP compliance

CE compliance

Option sample collection

Option helix coating

Option inlet adapter

Option outlet adapter

Option air extraction adapter

Option mini/micro-tablets

Option metal detector test tablet insert device KT2010

Option WIP manual/auto

Option 4 way drain valve system (drain/air exctraction/return)

Option hepa filter

Option empty capsule sorter KCS10

Option jam sensors

Option 2-way diverter manual KV2010 DT/WIP

Option 2-way diverter auto KV2020 DT/WIP

Option 2-12-way diverter auto V40000-V5000 DT/WIP

Option filling level sensors

Option air extraction monitoring

Option validation documentation

Option material certificates