High-end solutions tailored to your needs

KD7070

The knowledge and experience gained over the years allowed the development of another in a long line of Krämer firsts: The WIP deduster introduced in 2000. Pioneering innovations and continuous improvements to meet our customer's requirements have led to the new generation of KD70 WIP dedusters. They set another standard in high-containment (OEB5) in the production of highly active and potent products.

- Upward conveying range of 400 to 1600 mm

- Controller can be placed either on right or left side to guarantee best possible operation

- Quiet operation < 68 dB

- Featuring an acceleration sensor that assures constant vibration, independent of the load / amount of tablets in the deduster

- Vibration-free housing, patented drive unit

- Compact design, minimum footprint

- Easy assembly and disassembly, no tools are needed

- Efficient manual or automatic Wash-in-Place cleaning

- High-Containment for OEB5 (< 1 μg/m³) applications, including peripherals

- Classification: Atex Zone II 2D/- Db 140 °C

Conveying heights

400-1600 mm

Conveying Capacity

up to 6,3Mio tph

Tablet Inlet

The product inlet utilizes a Tri-Clamp flange for dust tight connections. The inlet can be rotated 360° independent of the outlet. With the use of optional inlet adapters, the deduster is easily adjustable to various tablet press discharge configurations.

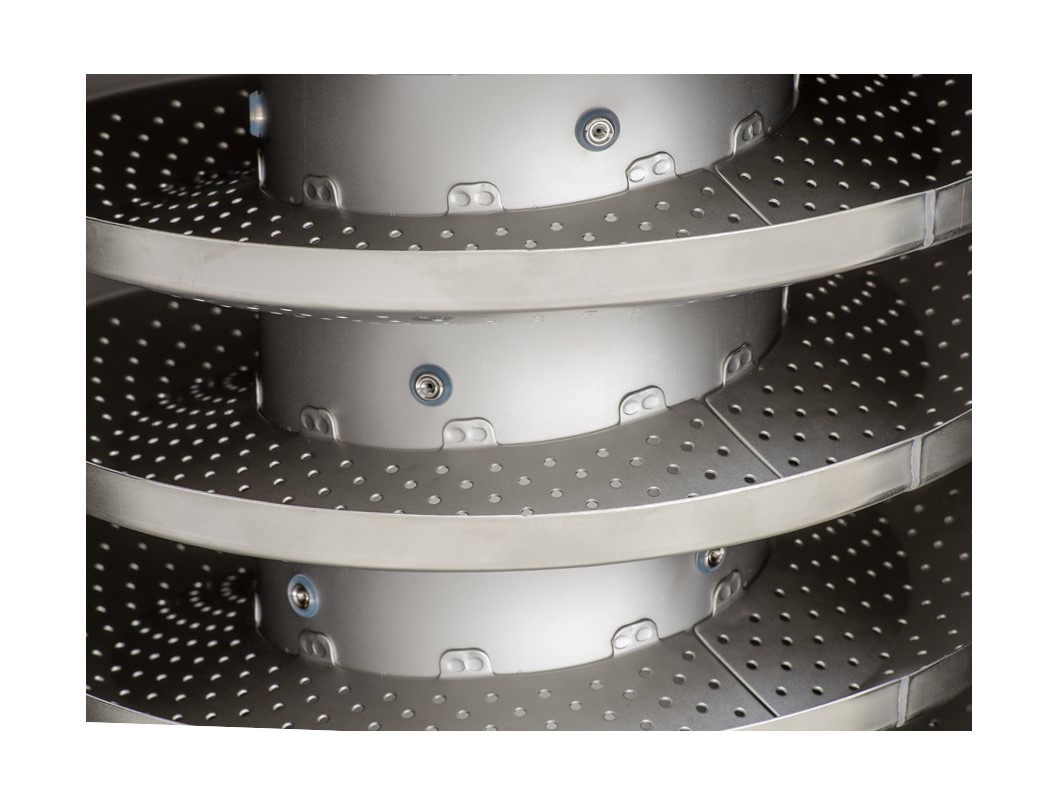

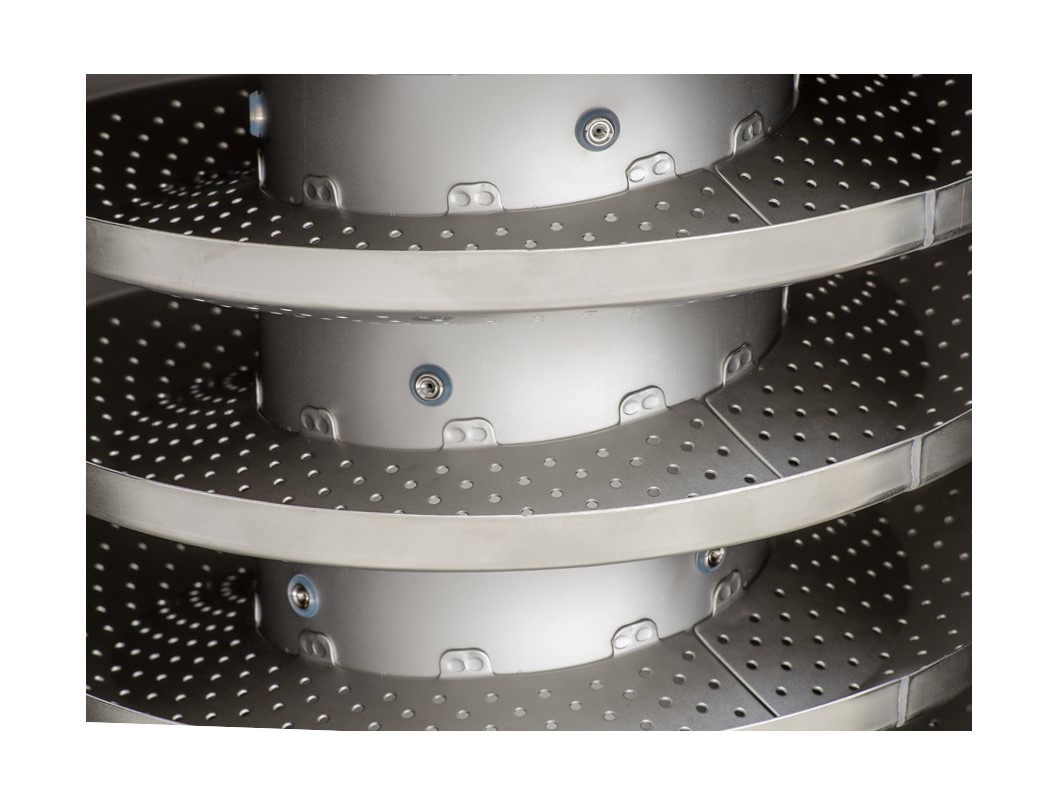

Helix

Helix with integral highly efficient washing nozzles for minimal water usage, less than 50 l/min. Innovative water supply through helix center column. Modular helix for easy assembly and disassembly, no tools are needed. Helix is capable of handling tablets from diameter 3-35 mm as well as all sizes of capsules.

OPTIMAL AND SECURE PROCESS INSIGHT

The KD7070 deduster has a dust-proof and removable PETG window for optimal process insight. The window is sealed against dust and water in order to meet the requirements for hazardous dusts OEB 5. The window allows easy access for easy removal of the helix for cleaning.

Easy to use control panel

The KD7070 utilize the KC7020 frequency controller. The KC7020 utilizes an acceleration sensor in the drive to determine the optimum operating frequency for ease of operation. The LCD screen allows the operator to turn the machine on and off, and to chose the necessary conveying speed to operate with the press. The KC7070 remote operation feature allows for connection and operation through the press controls if so equipped.

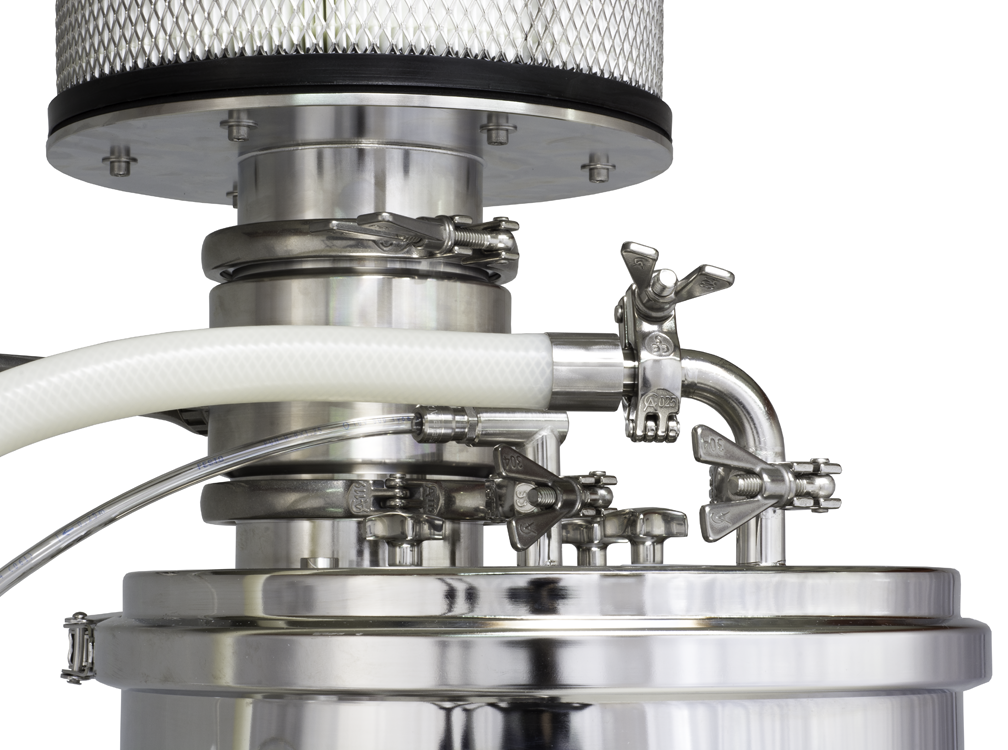

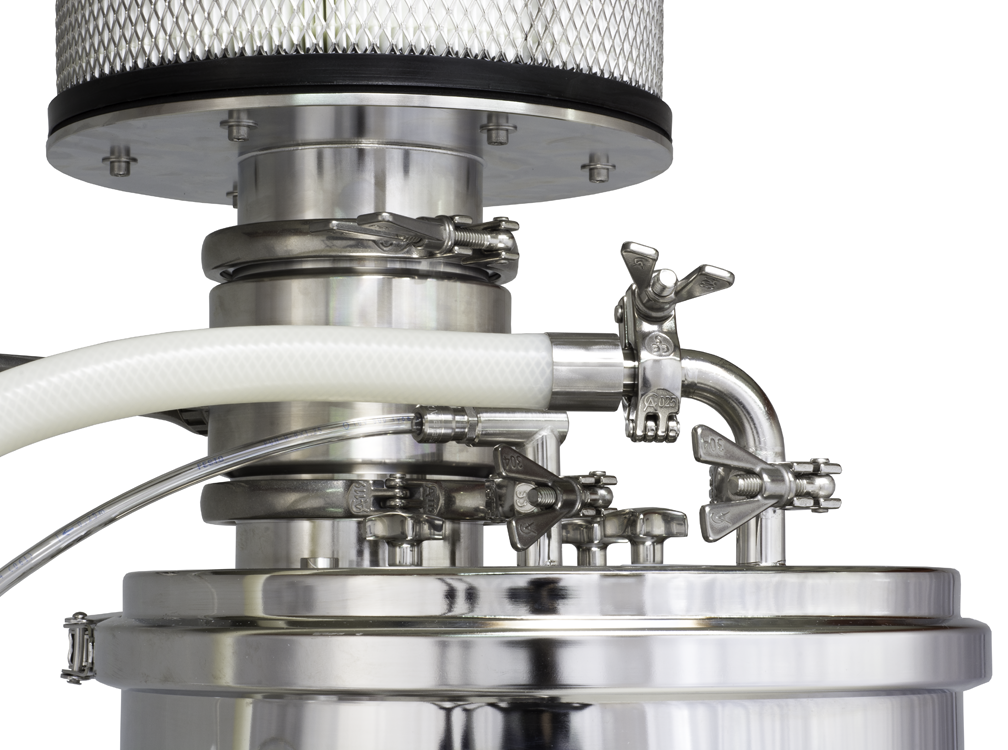

Filter

The optional HEPA filter class H14, manually actuated, ensures the highest safety for the operator.

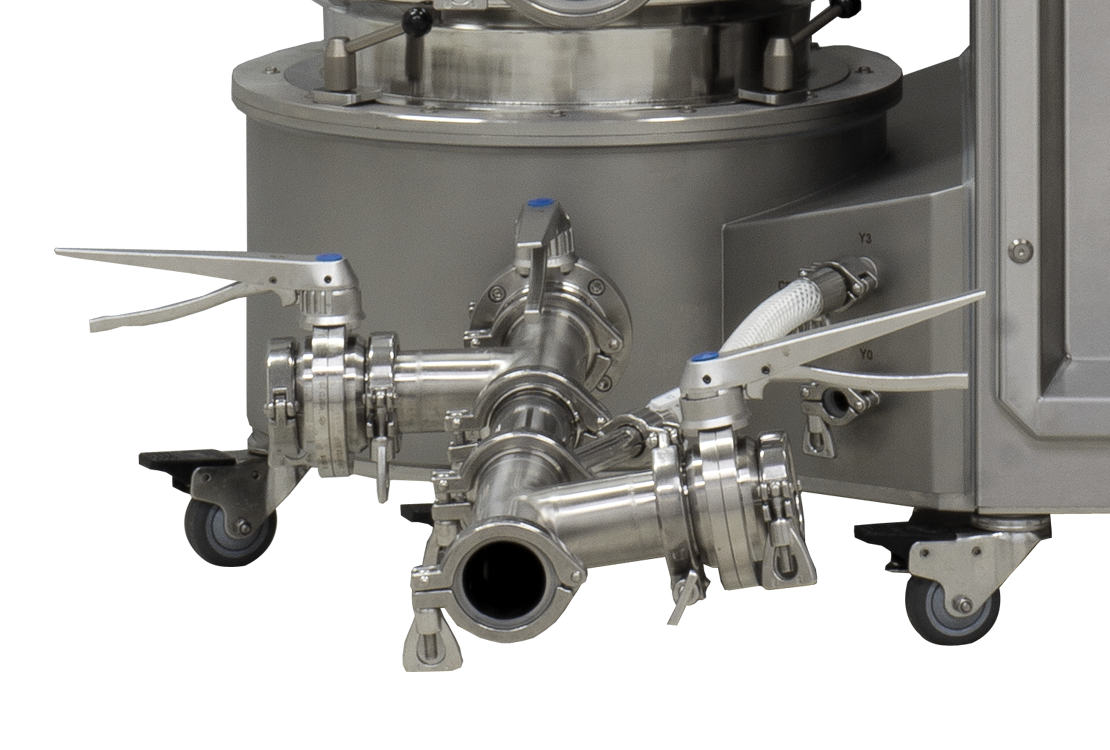

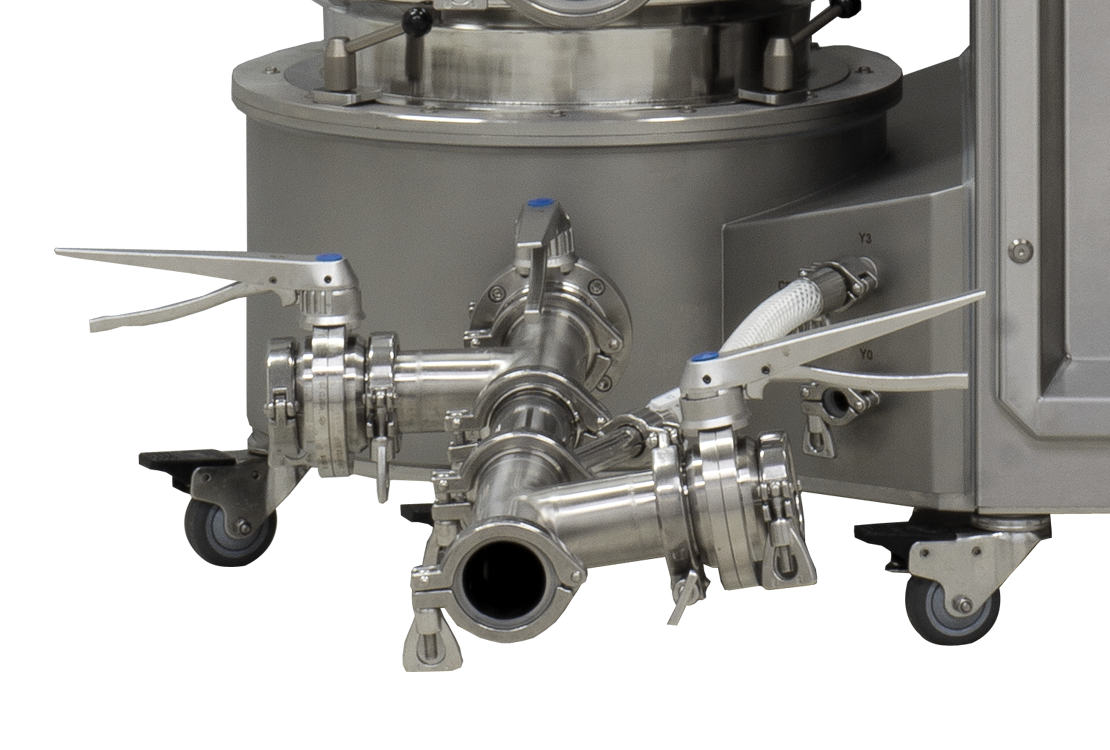

Drain Valves

The optional 4 way drain valve system can be manually actuated allowing for easy handling of the dust collection and water drain.

CONTAINMENT AND ATEX PERFORMANCE

The KD7070 deduster has been independently tested and certified to meet OEB 5 containment levels in accordance with ISPE – SMEPAC requirements as well as the EC Machinery Directive 2006/42/EC and Directive 94/9/EC (ATEX-95).

Specifications

Power Supply

110-240 V, 50/60 Hz

Peak current

3 A

Noise emission (1 m)

< 68 dB(A)

Elevation height

400-800-1200-1600 mm

Outlet height

905-2114 mm

Inlet height adjustable

Inlet height

471 mm

Total height

1514-2723 mm

Conveying technology

Upward conveying spiral

Drive unit technology

Pat. counter weight

Footprint

615-520 mm

Product contacting parts

AISI 316L, silicone, PET-G, PUR

Weight

110-170 kg

Compressed air

Ø6/4mm, 50-100 l/min (p=3-6 bar)

Air extraction

2" tri-clamp, 100-250m3/h (p=10-20 mbar)

Water consumption

16-46 l/min

Product inlet

ISO DN 65 tri-clamp

Product outlet

ISO DIN 65 tri-clamp

Protection rating drive unit

IP65

Protection rating housing/controller

IP65

Controller

Backlit LCD Screen with touchpad

Processing of tablets (var. forms ) Ø3-35 mm

Processing of mini/micro-tablets Ø1.5-3 mm

Processing of effervescent tablets Ø25-35 mm

Processing of capsules Nr. 4-00

Conveying speed mini/micro-tablets <Ø2.5 mm

10'300'000 tabs/h

Conveying speed tablet Ø5 mm

6'300'000 tabs/h

Conveying speed tablet Ø13 mm

574'000 tabs/h

Conveying speed tablet Ø20 mm

240'000 tabs/h

Conveying speed tablet Ø25 mm

95'000 tabs/h

Conveying speed tablet Oblong 16.3 x 7.6 x 5.7 mm

770'000 tabs/h

Conveying speed capsule size Nr. 4

300'000 caps/h

Conveying speed capsule size Nr. 3

300'000 caps/h

Conveying speed capsule size Nr. 2

300'000 caps/h

Conveying speed capsule size Nr. 1

300'000 caps/h

Conveying speed capsule size Nr. 0

300'000 caps/h

Conveying speed capsule size Nr. 00

250'000 caps/h

Explosion protection ATEX 94/9/EG

II 2D/- Db 140 °C

OEL Level acc. SMEPAC

OEB 5

cGMP compliance

CE compliance

Option sample collection

Option helix coating

Option inlet adapter

Option outlet adapter

Option air extraction adapter

Option mini/micro-tablets

Option metal detector test tablet insert device KT2010

Option WIP manual/auto

Option 4 way drain valve system (drain/air exctraction/return)

Option hepa filter

Option empty capsule sorter KCS10

Option jam sensors

Option 2-way diverter manual KV2010 DT/WIP

Option 2-way diverter auto KV2020 DT/WIP

Option 2-12-way diverter auto V40000-V5000 DT/WIP

Option filling level sensors

Option air extraction monitoring

Option validation documentation

Option material certificates